Humans have been coloring things since ancient times, using different combinations of plant and rock dyes, thanks to their ability to see all colors of the light spectrum. Powder Coating

Now, depending on what needs to be painted, we have a plethora of options available, ranging from the traditional acrylic brush paint to the sophisticated electrostatic powder coating.

And because your car project is similar to your child, and you want the best for it, we'll go over the advanced powder coating section here, which has a slew of advantages over other coating methods.

It's a mystery, really. As the name implies, the procedure entails applying an even coat of paint to a metallic piece in the form of electrically charged 30 to 50 micrometer paint particles that adhere to the part of the piece that is grounded, thereby creating a uniform finish.

Thank you for your help. How does it differ from the more traditional spray painting method, you might wonder?

As opposed to liquid paint, powder paint does not require the use of carrier fluids, which evaporate as the paint is applied to the surface. It is, therefore, less toxic, and you can apply a thicker coat because there will be no paint running or sagging during the application process.

Additionally, several powder colors can be applied before baking (curing) the part, and they will blend together in a single neat layer when baked (cured). In order for the layers to be neat, electrically charged particles must always seek out a surface area that is not covered by another layer, resulting in an even coat.

Perfect particle arrangement is maintained throughout the subsequent layers, resulting in a durable coating that will outlast traditional solvent-based paints by several months.

Does the powder coating booths come in a variety of colors?

Yes, there are two main types of thermosets and thermoplastics: elastomers and thermosetting polymers. The thermosets contain a cross-linker in their formula, and when the powder is baked, the cross-linker reacts with other chemicals to form polymers.

It is only during the baking process that the thermoplastics are allowed to flow into the final coating.

The procedure for applying powder coating.

Powder coating is completed in the same manner as other types of painting: 1.

It is necessary to clean the surface of the part to be painted using a variety of chemicals and mechanical methods to remove any contaminants such as oils and soil. Metal oxides and welding scales, lubrication greases, and other impurities must also be removed. It is possible for this part to include chemical pre-treatments involving phosphates or chromates in order to ensure a better surface bonding between the part and the color coat during manufacturing.

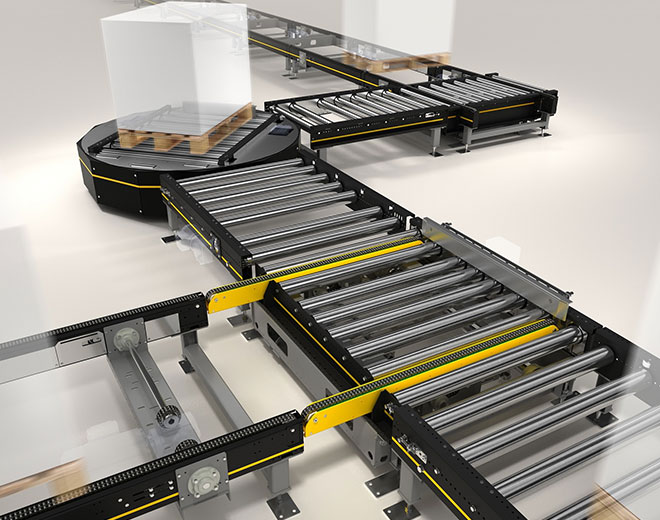

Using an electrostatic gun to spray the powder coating spraying production line is the most common method of doing so. It sprays powder particles onto the grounded object that needs to be painted after the powder particles have been charged positively by the gun.

Three-hundred-and-fortieth-anniversary Curing: After the desired layers of Powder Coating Equipment have been applied to the part, they must be allowed to merge and adhere to the surface, just as they would in Adobe Photoshop. A temperature of approximately 200 degrees Celsius (390 degrees Fahrenheit) for 10 minutes is used to accomplish this.

In the event that I am dissatisfied with the outcome, how do I get it off?

Organic solvents should be avoided at all costs because they have no effect on this type of coating at all. Use Methylene Chloride or Acetone to clean your surfaces. For those who are environmentally conscious and do not want to work with toxic materials, sandblasting is a viable alternative.

Are there any other considerations?

Check out the video below for more information, and keep in mind that for the best results, the powder coating operation should be carried out in a controlled enclosed environment where dust and other contaminants are prevented from coming into contact with the uncured layers of coating.